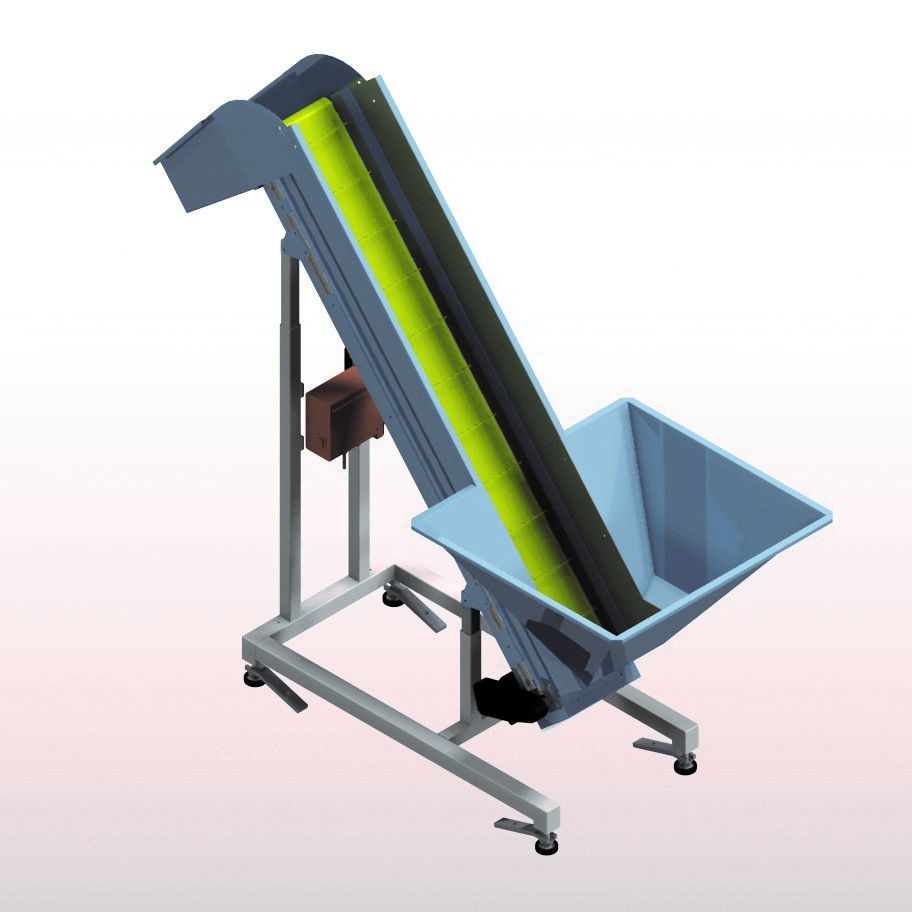

Structure of the hopper systems, type BBV

The structure of the hopper systems of type BBV is characterized by the following components:

Hopper system type BBV

Motor

Hopper control

Conveyor belt

Characteristics of hopper systems, type BBV

- Prolonged autonomous feeding system running time

- Large hopper volumes prolong the manual refilling cycles and increase the efficiency of the entire system.

- The feeding unit's susceptibility to failure is reduced decisively by the constant charges.

- Filling volume: 45-350 liters, max. filling weight: 75 kg

- Storage and dispensing of lightweight, bulky parts

- Conveyor belt with the part-dependent driver cleats

- Base frame with positioning feet or rollers

- Quick-emptying flap for fast type change

- Grimm retaining function for gentle part handling

You can get detailed information about our accessory components in the download area.