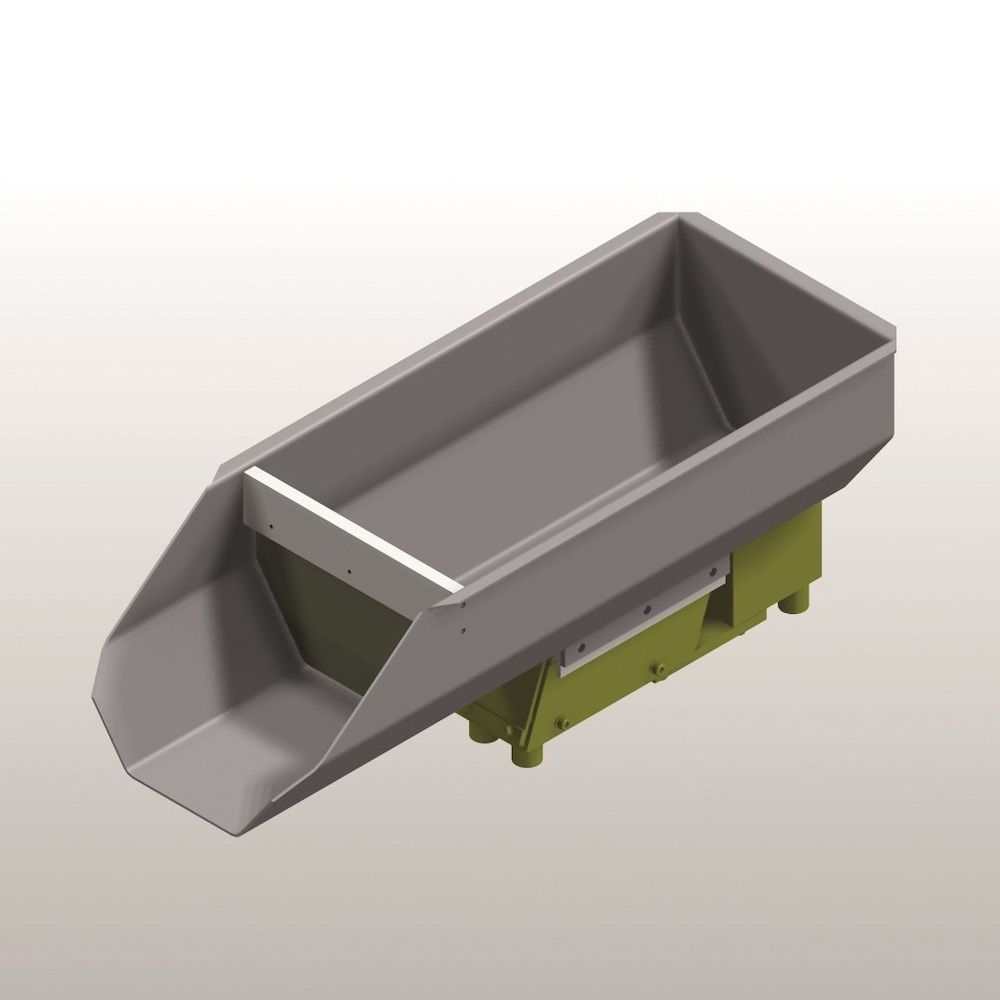

Structure of the hopper systems, type VNB

The structure of the hopper systems of type VNB is characterized by the following components

Hopper system type VNB

Linear conveyor

Hopper chute

Characteristics of hopper systems, type VNB

- Prolonged autonomous feeding system running time

- The feeding unit's susceptibility to failure is reduced decisively by the constant charges.

- Due to the oscillating conveyor drive, the type VNB is referred to as a vibration hopper.

- Easy-to-clean, smooth hopper chute made of V2A steel prevent parts from getting jammed.

You can get detailed information about our accessory components in the download area.