High speed delivery of complex component

Centrifugal feeder

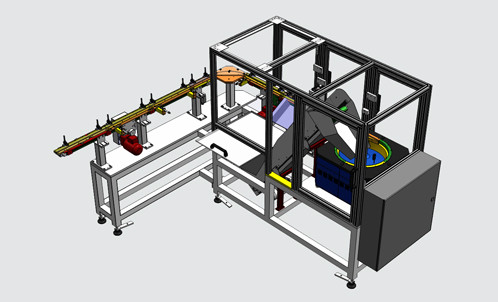

Grimm solution, centrifugal feeder for small plastic parts

Application

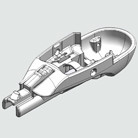

- One type of plastic part (see picture)

- Orientation required for further assembly

- Selected from bulk quantity

- Feed rate: approx.128 parts/minute

- Independent system with PLC and guarding

Proposal

- Feeding system with centrifugal feeder type ZF50 and hopper system type BBV

- Parts loaded into the hopper system at random, in bulk quantity for transfer from the hopper system into the centrifugal feeder, controlled by an automatic level switch.

- Parts are initially transported in single file end to end inline at random

- Aligned parts transfer onto a conveyor passing a line scan camera for orientation selection

- Parts with the incorrect orientation return into the hopper system to be recirculated

- High speed capability of the ZF50 - provides an output of 128 parts/minute (with correct orientation)

- Parts with the correct orientation continue via a 2 metre length of horizontal linear powered track, which includes a 90 degree arc. The track incorporates three pneumatic retaining chambers to separate the parts in to groups of ten, preventing jamming due to excessive back pressure

- Efficient delivery of parts is maintained by means of an automatic fault-clearing function