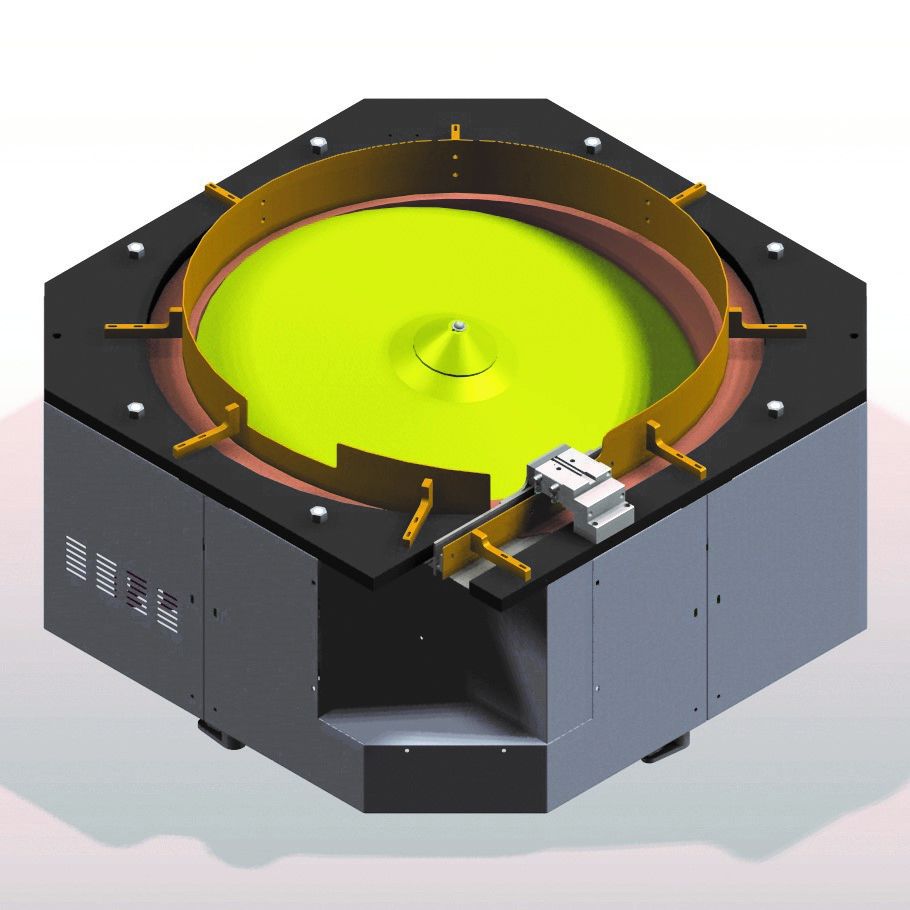

Structure of the centrifugal feeder

The structure of the centrifugal feeder is characterized by the following components:

Centrifugal Feeders

Sorting baffles / part feeding

Turning plate (tilted by 10 degrees)

Discharge ring, horizontal

Characteristics of Grimm centrifugal feeder

- High-speed feed with capacities of up to 1000 parts/min and more

- Suitable for lightweight mass production parts with simple sorting criteria and for massive steel parts.

- Fast type change thanks to plug-in sorting elements

- Gentle part handling (without vibrations): Parts lie still on the turning plate when there is a rotary movement

- Robust design with hardened sorting baffles

- Separate speeds for turning plate and discharge ring

You can get detailed information about our accessory components in the download area.